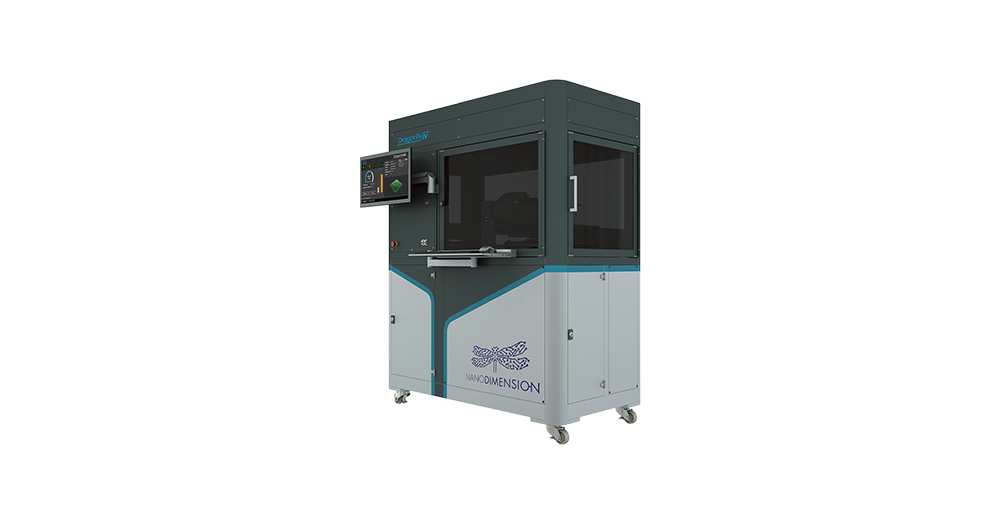

DragonFly IV

Description

Additively Manufactured Electronic (AME) functional circuits and devices can now be produced 24/7 with little to no operator intervention using the DragonFly IV Lights-out Digital Manufacturing printer. A Nano Dimension product, the DragonFly IV precision additive manufacturing system is the most advanced platform for rapid prototyping and low-volume manufacturing of high resolution, multilayered 3D printed electronics.

The DragonFly IV Lights-Out Digital Manufacturing system is the industry’s only comprehensive additive manufacturing platform for around-the-clock 3D printing of electronic circuitry. This precision additive manufacturing platform uniquely integrates an extremely precise inkjet deposition printer with dedicated nano-inks and optimized 3D software to print electronic circuits such as antennas, capacitors and sensors.

With the DragonFly IV designers can move rapidly from concept and design validation to production of precision electronic components, while keeping the entire process securely in-house. Companies can now reduce demand on prototyping and short-run manufacturing resources and lower the total cost of operation in comparison to traditional manufacturing methods.

The DragonFly IV incorporates proprietary, state-of-the-art technology that enables 24/7 uninterrupted 3D printing, streamlined workflows and easy operation. Users can now reduce demand on prototyping and short-run manufacturing resources and lower total cost of operation in comparison with traditional manufacturing methods. Enhanced purging and washing systems that increase print heads stability and optimize ink consumption.

Features:

- High Print Quality

- Smart Management for Printer uptime

- Simple and Fast Opertion

- Automatic print head maintenance and cleaning system